The new iPhone 17 lineup is a masterclass in materials science. The impossibly thin Slim needs titanium’s strength, while the powerhouse Pro needs aluminum’s cooling. Here’s the engineering story behind the switch.

Every September, after Apple’s big iPhone event, we all rush to compare the spec sheets. We obsess over camera megapixels, chip benchmarks, and battery life. But this year, one of the most interesting stories isn’t about the silicon inside the phones, but the metal wrapped around them.

Looking at the lineup, you’ll see a decision that seems, on its face, completely backward. The new, ultra-premium iPhone 17 Slim is forged from a beautiful titanium frame. Yet, the most powerful, most expensive iPhone 17 Pro has reverted to an aluminum unibody.

After years of climbing the ladder from aluminum to stainless steel and finally to titanium, why would Apple “demote” its top-tier phone? The answer isn’t about cost-cutting. It’s about physics, and it reveals everything about Apple’s strategy for each device.

To understand why this is such a big deal, you have to remember where we’ve been. For years, the standard iPhone used aluminum. It was light and durable, but starting with the iPhone X, Apple moved its Pro models to a polished stainless steel frame. It was heavier and felt more substantial—more “premium.” But it was also a fingerprint magnet and incredibly dense.

Then came the iPhone 15 Pro, which made the leap to titanium. It was the best of both worlds: stronger than steel but significantly lighter. It felt like the pinnacle of smartphone materials, the final destination. We all assumed titanium was here to stay.

So, when Apple announced that the iPhone 17 Pro, its most powerful phone ever, was going back to aluminum, it felt like a step back. But it wasn’t. It was a deliberate, calculated engineering choice driven by the Pro’s single biggest challenge: heat.

The Pro Performance Needs to Breathe

The “Pro” name on an iPhone no longer just means a better camera. It means pro-level performance for gaming, video editing, and running the complex on-device models for Apple Intelligence. The new A19 Pro chip is a monster, with a 6-core GPU and hardware-accelerated ray tracing. But all that power generates an enormous amount of an old enemy: heat.

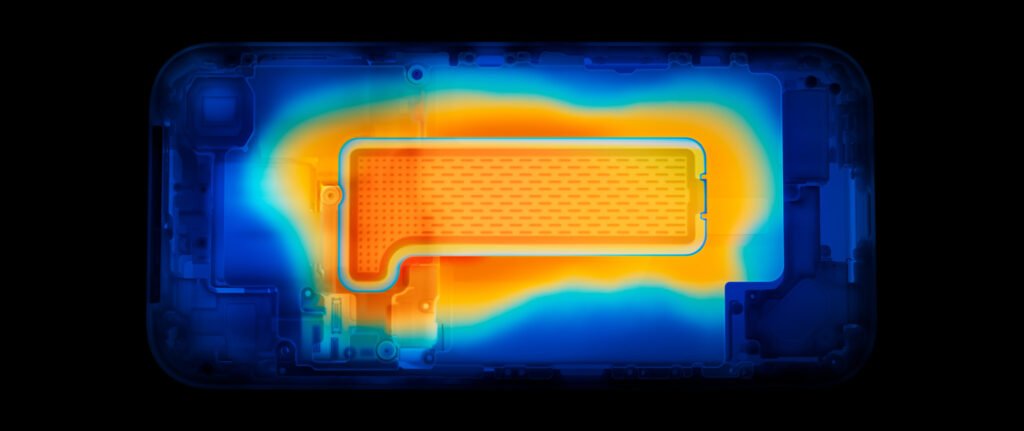

If you can’t get rid of that heat, the chip has to slow itself down to prevent damage. This is called thermal throttling, and it’s the kryptonite of sustained performance. You can have the fastest chip in the world, but if it can’t stay cool, it’s useless after a few minutes of intense gaming.

This is where titanium’s one major weakness comes into play. While it’s strong and light, titanium is a terrible conductor of heat. It essentially traps heat inside the phone’s chassis.

Apple’s solution for the iPhone 17 Pro was a new internal vapor chamber cooling system, but that system needs to dump the heat it collects somewhere. That “somewhere” is the phone’s body. And this is why Apple went back to aluminum. Aluminum is a fantastic thermal conductor—in fact, Apple stated it has 20 times the thermal conductivity of titanium. The entire aluminum unibody of the iPhone 17 Pro acts as a giant heatsink, drawing warmth away from the A19 Pro chip and dissipating it into the air.

For the Pro model, the primary engineering goal wasn’t a marketing buzzword; it was sustained performance. They chose the material that would let the chip run at its peak for longer. It’s a true “Pro” decision, prioritising function over form.

The iPhone 17 Slim Challenge: Strength Without the Bulk

So if aluminum is so great, why isn’t the new iPhone 17 Slim made of it? Because the Slim had a completely different engineering problem to solve.

The goal here was to create a device that is an astonishing 5.64mm thin and weighs only 165 grams. When you make a device that thin, its biggest enemy is fragility. The ghost of “Bendgate” from the thin iPhone 6 and 6 Plus looms large in Apple’s history. Making the Slim out of aluminum would have required making the frame thicker to maintain rigidity, which would have defeated the entire purpose of the phone.

This is where titanium’s primary superpower shines: its incredible strength-to-weight ratio. Grade 5 titanium provides the immense structural rigidity needed to build such a thin chassis without it snapping in half the first time you put it in your back pocket. Stainless steel would have been strong enough, but it would have made the phone feel like a lead weight, ruining the light, airy feel that defines the device.

For the iPhone 17 Slim, the goal was to achieve an impossible form factor. Titanium was the only material that could provide the necessary skeleton-like strength in such a light and impossibly thin package.

If you think about it, Apple’s material choices aren’t contradictory at all; they’re perfectly logical. They show a company making sophisticated engineering trade-offs that serve the core identity of each product.

The iPhone 17 Pro is a performance machine, and its aluminum body is its radiator. The iPhone 17 Slim is a design object, and its titanium frame is its skeleton.

Apple didn’t “go backwards” by using aluminum. Instead, they showed they’re willing to pick the right tool for the right job, even if it doesn’t sound as fancy on a marketing page. And that’s a far more “Pro” move than just sticking with a material for its name alone.